- Manufacturing

- November 16, 2024

Blockchain-Based Inventory Records for Manufacturing

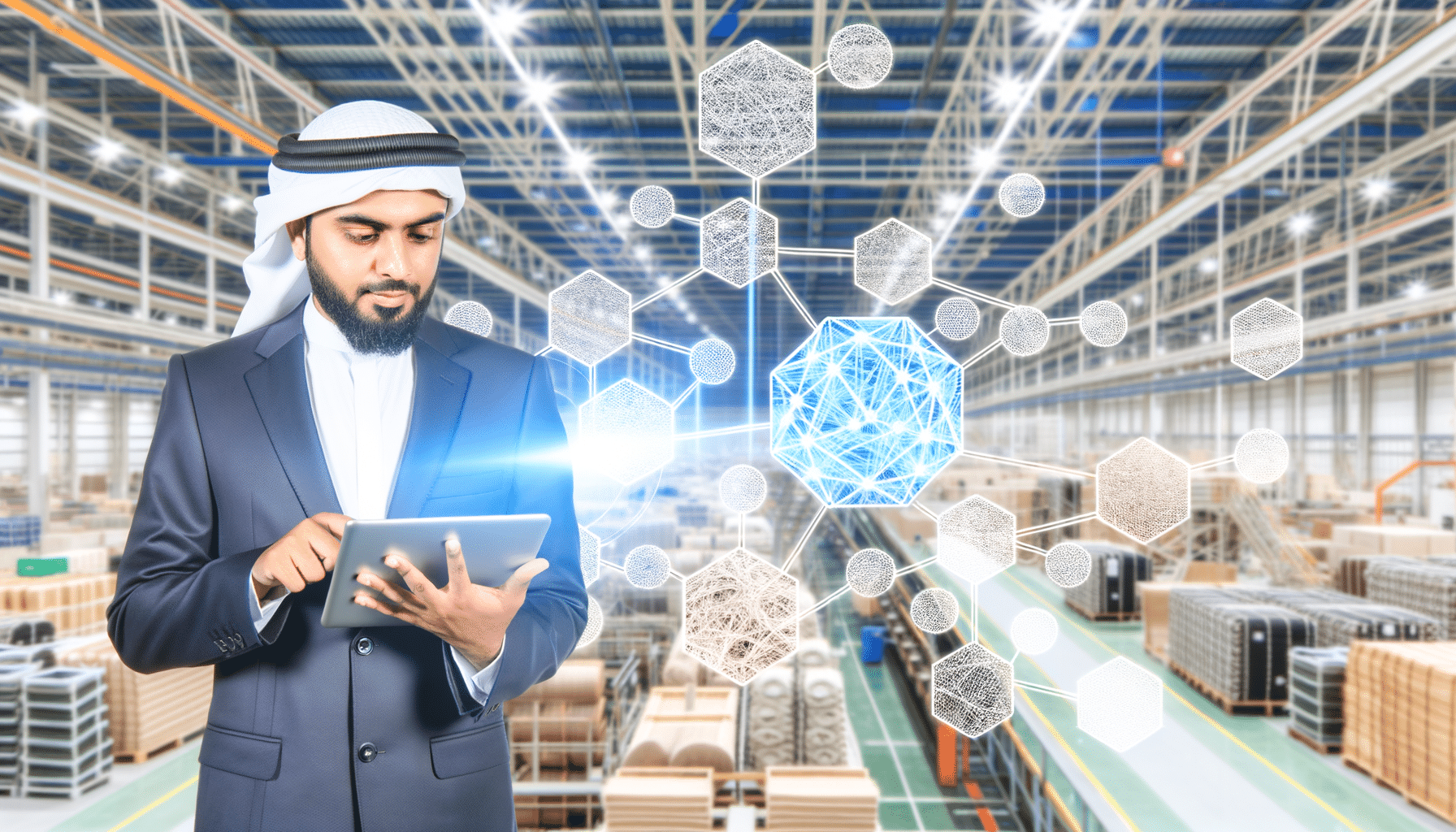

As I delve deeper into the world of manufacturing, one thing becomes increasingly clear: inventory management is the linchpin of a successful operation. In the fast-paced and complex landscape of manufacturing, where every second counts, the precision and efficiency of inventory tracking can make or break the process. In exploring transformative solutions, I found that there’s no better friend to manufacturers than blockchain technology.

Manufacturing’s Critical Challenge: Inventory Management

The manufacturing industry, with its intricate supply chains, often grapples with inventory mismanagement. The challenges arise from inaccurate demand forecasting, inefficient tracking systems, and, sometimes, unscrupulous activities. Traditional inventory management methods are insufficient for the agility that modern manufacturing demands, leading to increased costs and decreased productivity.

From parts suppliers to logistics, every link in the manufacturing chain relies heavily on accurate and timely inventory records. Here, blockchain technology presents a game-changing opportunity.

What Makes Blockchain Perfect for Manufacturing Inventory?

Blockchain is not just a buzzword you hear floating around tech circles; it’s a robust system recognized for its unparalleled security and transparency. By decentralizing and encrypting data, blockchain ensures that the information it holds is immutable. This means no more tampered records or unauthorized alterations — a significant boon for inventory management.

Benefits of Blockchain for Inventory:

- Transparency: Every transaction is recorded on the blockchain ledger, promoting a transparent supply chain where data is available to all stakeholders.

- Traceability: Real-time tracking becomes a reality, enabling manufacturers to pinpoint the exact location of an item at any stage of production.

- Security: The cryptographic nature of the blockchain means records are tamper-proof, greatly reducing the risk of fraud.

- Cost-Effectiveness: By minimizing errors and improving efficiency, blockchain reduces operational costs related to inventory management.

Revolutionizing Inventory with Blockchain

Incorporating blockchain into inventory management systems elevates the manufacturing process to a whole new level. But, how exactly does it work? It’s all about data — and ensuring that data is consistent, reliable, and accessible.

Steps to Implement Blockchain in Inventory Management:

- Identify Needs: Understand the specific challenges in your current inventory processes.

- Select the Right Blockchain Platform: Not all blockchain solutions are created equal; choose one that aligns with your operational objectives.

- Integrate with Existing Systems: Ensure your blockchain system works seamlessly with existing applications for smooth adoption.

- Train Your Team: Make sure your staff is well-versed in operating and troubleshooting the new system.

The Future of Manufacturing

As the industry pivots towards digitization, blockchain-enabled inventory systems are poised to become standard. They can transform manufacturing by ensuring accuracy and optimizing efficiency — heralding a future where every bolt and screw is accounted for in real-time.

Moreover, the integrated nature of blockchain makes it an invaluable tool for addressing regulatory compliance issues, thereby saving on potential fines and sanctions. Its incorporation into manufacturing processes sets a precedence for leveraging advanced technologies to solve age-old problems.

Concluding Thoughts: Embrace the Change

By adopting blockchain-based inventory systems, manufacturers are not just staying ahead of the curve but paving the way. The advantages are clear in enhancing inventory management and offering a competitive edge. It’s a smart strategy to integrate blockchain into your operations — allowing you to refocus your efforts on quality and innovation.

I encourage you to explore RecordsKeeper.AI, which melds AI and blockchain to deliver optimal record management solutions. The future of manufacturing is blockchain-powered, efficient, and unstoppable. Embrace the change, and watch as it propels your business forward.

Stay connected and follow my journey as I delve deeper into these innovations, continuing to uncover how technology reshapes industries and optimizes efficiency. Together, we can create a world where records not only secure our operations but empower them.

Toshendra Sharma is the visionary founder and CEO of RecordsKeeper.AI, spearheading the fusion of AI and blockchain to redefine enterprise record management. With a groundbreaking approach to solving complex business challenges, Toshendra combines deep expertise in blockchain and artificial intelligence with an acute understanding of enterprise compliance and security needs.

Related Posts

Document Control in Manufacturing Plants

Managing records in production environments.

- December 21, 2024

Blockchain for Ethical Sourcing in Manufacturing

Promoting ethical sourcing in manufacturing through blockchain.

- November 16, 2024

Archives

- December 2024

- November 2024

- October 2024

- September 2024

- August 2024

- July 2024

- June 2024

- May 2024

- April 2024

- March 2024

- February 2024

- January 2024

- December 2023

- November 2023

- October 2023

- September 2023

- August 2023

- July 2023

- June 2023

- May 2023

- April 2023

- March 2023

- February 2023

- January 2023

- December 2022

- November 2022

- October 2022

- September 2022

- March 2019

Want to get more content like this?

Signup to directly get this type of content to your inbox!!

Latest Post

Organizing External Auditor Access

- December 22, 2024

Document Control in Manufacturing Plants

- December 21, 2024

Handling Rush Financial Report Requests

- December 20, 2024

Managing Record Access After Staff Changes

- December 19, 2024